Image gwsmasonry.com

Selecting the Ideal Tool for Concrete Drilling

Choosing the correct tool for concrete drilling is not just about getting the job done. It’s about efficiency, precision, and the longevity of both your tools and the structures you’re working on. In the realm of concrete work, the concrete hole saw emerges as a prominent option, revered for its precision and effectiveness.

Yet, alternatives abound, each with unique benefits suited to specific project needs. This guide demystifies the selection process, providing insights into the concrete hole saw and its contenders.

Understanding Concrete Drilling Needs

Concrete drilling is not a one-size-fits-all task. Projects vary widely, demanding a nuanced approach to tool selection. Factors like hole size, desired depth, and the precision of the cut play pivotal roles in dictating the appropriate equipment.

Moreover, the type of material, be it standard concrete, reinforced varieties, or other masonry alongside the project’s scale, influences the choice. Recognizing these variables is the first step towards selecting a tool that not only fits the job but enhances the quality and efficiency of your work.

Overview of Tools for Concrete Drilling

In the world of concrete drilling, several tools stand out for their specific capabilities and applications. Here’s a brief overview of some key players:

| Tool/ Criteria | Tool Type | Primary Use | Suitable Materials | Precision | Efficiency | Cost | Required Skill Level |

|---|---|---|---|---|---|---|---|

| Concrete Hole Saw | Specialized Saw | Cutting circular holes | Concrete, Masonry | High | Moderate | Moderate | Moderate |

| Rotary Hammer Drill w/ Core Bit | Drill | Drilling/coring | Concrete, Reinforced concrete | Moderate | High | High | High |

| Diamond Core Drill | Specialized Drill | Large diameter holes | Concrete, Stone | High | High | High | High |

| Carbide Tipped Hole Cutter | Cutter | Smaller holes | Concrete, Metal | Moderate | High | Moderate | Moderate |

| Masonry Drill Bits | Drill Bit | Drilling holes | Concrete, Masonry | Low-Moderate | Moderate | Low | Low |

| Angle Grinder w/ Diamond Blade | Power Tool | Cutting, grinding | Various, incl. Concrete | Moderate | High | Moderate | Moderate |

| Chisel and Hammer | Manual Tool | Manual hole making | Concrete, Masonry | High | Low | Low | Low-Moderate |

| Air Percussion Drill | Drill | Drilling | Concrete, Masonry | Moderate | High | Moderate-High | High |

| SDS Drill | Drill | Heavy-duty drilling | Concrete | Moderate | High | High | High |

| Oscillating Multi-Tool w/ Carbide Blade | Multi-Tool | Cutting, sanding | Various | High | Moderate | Moderate | Moderate |

| Water Jet Cutter | Machine | Precision cutting | Any Material | Very High | High | Very High | Very High |

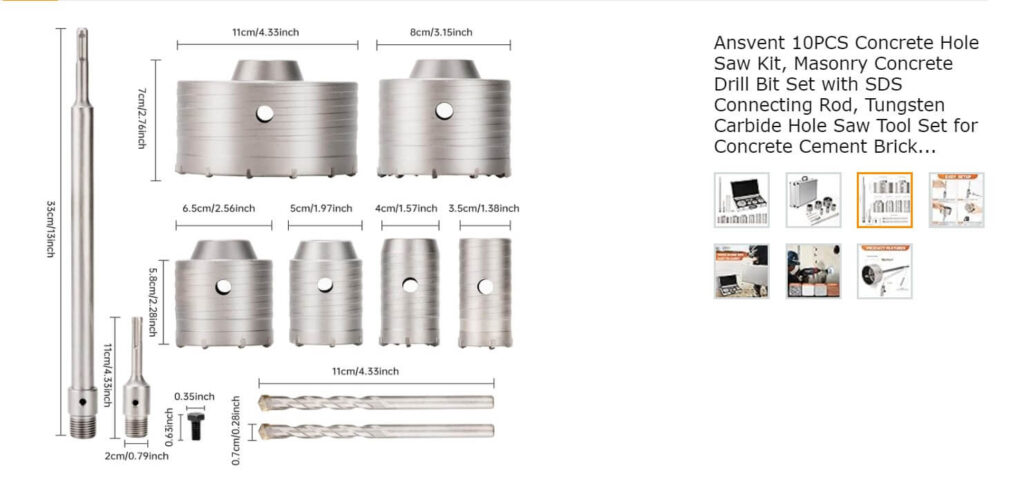

Concrete Hole Saw

The Concrete Hole Saw is designed for precision, making it the go-to for creating clean, circular cuts through concrete. Ideal for installing conduit, pipes, and more, this tool combines power with finesse, ensuring minimal damage to surrounding areas.

Rotary Hammer Drill with Core Bit

A powerhouse in the drilling world, the Rotary Hammer Drill, when fitted with a Core Bit, can tackle the toughest materials, including reinforced concrete. It’s perfect for jobs requiring deep, wide holes, offering speed and efficiency without compromising on precision.

Diamond Core Drill

For projects demanding utmost precision and care, the Diamond Core Drill shines. Capable of cutting through the hardest materials with minimal effort, this tool is the epitome of clean, accurate drilling, especially for substantial diameters and depths.

Carbide Tipped Hole Cutter

The Carbide Tipped Hole Cutter excels in making quick, sharp cuts through concrete and metal alike. While it may not match the depth capabilities of core drills, its efficiency and speed in creating smaller, precise holes make it invaluable for specific tasks.

Masonry Drill Bits

Masonry Drill Bits are the quintessential tools for drilling into concrete, brick, and stone. These bits are used with standard drills and are perfect for smaller, straightforward holes. Their versatility and accessibility make them a staple in both professional and DIY toolkits.

Angle Grinder with Diamond Blade

An Angle Grinder equipped with a Diamond Blade transforms into a potent tool for cutting, grinding, and shaping concrete. While not primarily a drilling tool, its ability to make precise cuts and adjustments in concrete surfaces is invaluable for many construction and renovation projects.

Chisel and Hammer

The traditional duo of Chisel and Hammer speaks to the art of manual labor. Though requiring more time and physical effort, this combination allows for detailed adjustments and is often used for minor corrections or when precision is paramount over speed.

Air Percussion Drill

The Air Percussion Drill, utilizing compressed air to drive the drilling action, offers a unique balance of power and precision. This tool is particularly suited for drilling in hard, brittle surfaces where control over the drilling speed and impact is crucial.

SDS Drill

An SDS Drill (Slotted Drive System) is designed for heavy-duty drilling into concrete and masonry. Its specialized design allows for efficient hammer action with less effort from the user, making it ideal for larger, more demanding drilling tasks.

Oscillating Multi-Tool with Carbide Blade

The Oscillating Multi-Tool with a Carbide Blade is a versatile addition to any toolkit, capable of cutting, grinding, and scraping. When used with a carbide blade, it can make precise cuts in concrete, though it is more suited for smaller, detail-oriented tasks rather than deep or wide drilling.

Water Jet Cutter

The Water Jet Cutter stands out for its ability to cut through concrete with precision and without generating dust or vibrations. Using high-pressure water mixed with an abrasive substance, it can cut through the thickest concrete, offering a dust-free alternative to traditional drilling and cutting methods.

Each of these tools brings something unique to the table, from the simplicity and precision of manual chiseling to the advanced technology of water jet cutting. Selecting the right tool requires careful consideration of the project’s specific needs, including the material, the precision required, and the project’s overall scope.

Criteria for Comparison

When comparing tools for concrete drilling, several criteria are essential for making an informed decision. Understanding these factors can help select the right tool for specific project needs. Here’s a breakdown of the key comparison criteria:

Tool Type

This refers to the basic categorization of the tool, such as whether it’s a drill, saw, cutter, or grinder. The tool type can give a quick indication of its general application and suitability for certain tasks.

Primary Use

Identifies the main function or purpose of the tool. Some tools are designed for precise drilling operations, while others may excel in cutting, grinding, or chiseling. Understanding the primary use is crucial for matching the tool to the job.

Suitable Materials

Different tools are optimized for different materials. While all the tools discussed are suitable for concrete, some may also be ideal for masonry, brick, stone, or even metal. Selecting a tool that matches the material of your project is vital for effectiveness and tool longevity.

Precision

The level of accuracy and the quality of finish provided by the tool. Precision is particularly important for tasks requiring exact hole sizes, clean cuts, or delicate modifications to existing structures.

Efficiency

Efficiency encompasses the tool’s speed, ease of use, and the energy or effort required to achieve the desired results. Tools that offer high efficiency can save time and reduce labor costs on a project.

Cost

The initial investment required to purchase the tool, as well as ongoing costs associated with maintenance, accessories, and replacement parts. Balancing cost with the quality and capabilities of the tool is a key consideration.

Required Skill Level

This criterion considers the level of expertise or experience necessary to operate the tool effectively and safely. Some tools may be more user-friendly for DIY enthusiasts, while others require professional training or significant experience.

Evaluating each tool against these criteria provides a comprehensive understanding of its capabilities and limitations. This approach ensures that the selection process is guided by practical considerations, aligning the tool’s features with the project’s specific requirements.

Detailed Comparison

Tool Type and Primary Use

In the realm of concrete drilling and modification, tools range from highly specialized to remarkably versatile. The Concrete Hole Saw and Diamond Core Drill, for instance, are specialized tools designed primarily for making precise holes in concrete and masonry. Their design and functionality are tailored for specific tasks, ensuring high precision and efficiency but limiting their versatility.

Conversely, tools like the Angle Grinder with Diamond Blade and the Oscillating Multi-Tool with Carbide Blade boast a broader range of applications. Beyond drilling or cutting holes, they can grind, shape, and finish concrete and other materials, making them invaluable for projects requiring multiple types of modifications.

The Rotary Hammer Drill with Core Bit and the SDS Drill strike a balance between specialization and versatility. While they are optimized for drilling through hard materials, their design allows for a range of drilling diameters and depths, adapting to various project needs without sacrificing precision.

Suitable Materials

Choosing the right tool also depends on the material at hand. While all the discussed tools can work with concrete, their effectiveness may vary based on the concrete’s type and condition (e.g., reinforced, aged, or precast concrete).

- For dense, reinforced concrete, the Diamond Core Drill stands out for its ability to cut through with minimal effort, thanks to the diamond-tipped bits. Similarly, the Rotary Hammer Drill with Core Bit, equipped with a durable core bit, can efficiently penetrate reinforced concrete, handling the steel reinforcement with ease.

- In the case of non-reinforced or softer concrete types, options like the Carbide Tipped Hole Cutter and Masonry Drill Bits offer sufficient performance, providing clean cuts without the need for the heavy-duty capabilities of diamond-tipped tools.

- For detailed work or modifications to masonry and brick, the Chisel and Hammer offer unparalleled control, allowing for precise adjustments where precision outweighs speed. Similarly, the Oscillating Multi-Tool with Carbide Blade can be an excellent choice for precision work in less dense materials, offering versatility for cutting and finishing tasks.

- Air Percussion Drills and SDS Drills are well-suited for a variety of concrete types, offering a balance of power and control. Their design allows for effective drilling in both reinforced and non-reinforced concrete, with SDS Drills being particularly adept at handling larger, more demanding projects.

Precision and Efficiency

Precision and efficiency are paramount when selecting the right tool for concrete drilling and cutting:

- Concrete Hole Saws and Diamond Core Drills offer exceptional precision for drilling circular holes, making them ideal for installations where accuracy is crucial. Their efficiency, however, is often contingent on the material’s hardness and the tool’s power source.

- Rotary Hammer Drills with Core Bits excel in efficiency, quickly penetrating concrete with less effort, especially in repetitive tasks or larger projects. While precise, the finish may require additional work for a perfectly smooth surface.

- Carbide Tipped Hole Cutters are efficient for smaller holes in softer concrete or masonry, providing good precision with a faster operation than manual tools but slightly less than diamond-tipped tools.

- Masonry Drill Bits, used with standard drills, offer moderate precision and efficiency, suitable for small to medium-sized projects where ultra-precision is not the top priority.

- Angle Grinders with Diamond Blades and Oscillating Multi-Tools with Carbide Blades provide versatility and precision in cutting and shaping, though their efficiency can vary based on the blade’s quality and the material’s hardness.

- Chisel and Hammer represent the manual approach, offering maximum control and precision at the cost of efficiency and speed.

- Air Percussion Drills and SDS Drills are designed for high efficiency in drilling through tough materials, with precision that satisfies most construction standards.

- Water Jet Cutters, while not commonly used for standard drilling tasks, offer unparalleled precision and efficiency in cutting through thick concrete without generating dust or vibrations, albeit at a significantly higher cost.

Cost

The initial investment and long-term value of concrete drilling tools can vary widely:

- Concrete Hole Saws and Diamond Core Drills represent a higher upfront cost, especially for high-quality diamond-tipped models, but offer durability and precision that can justify the expense over time.

- Rotary Hammer Drills with Core Bits and SDS Drills require a moderate to high initial investment but are known for their longevity and versatility, making them a valuable asset in professional toolkits.

- Carbide Tipped Hole Cutters and Masonry Drill Bits are more budget-friendly, offering a cost-effective solution for smaller projects without compromising significantly on performance.

- Angle Grinders with Diamond Blades and Oscillating Multi-Tools with Carbide Blades involve moderate initial costs with the added expense of replacement blades or attachments over time.

- Chisel and Hammer are the most economical in terms of initial investment, though labor-intensive.

- Air Percussion Drills sit in the mid to high range of initial costs, with the need for an air compressor adding to the overall investment.

- Water Jet Cutters entail a significant initial investment, suitable primarily for industrial applications where their unique capabilities can be fully utilized.

Required Skill Level

The learning curve and expertise required for each tool also influence their suitability for different users:

- Concrete Hole Saws, Diamond Core Drills, and Rotary Hammer Drills with Core Bits require a moderate level of skill to operate effectively, with safety training recommended for optimal use.

- Masonry Drill Bits, Angle Grinders with Diamond Blades, and Oscillating Multi-Tools with Carbide Blades are accessible to DIY enthusiasts, though experience and caution are advised for precision tasks.

- Chisel and Hammer demand manual skill and patience, suitable for those comfortable with traditional masonry techniques.

- Air Percussion Drills and SDS Drills necessitate familiarity with heavy-duty drilling equipment and safety precautions, typically requiring professional expertise.

- Water Jet Cutters involve advanced operational knowledge and safety considerations, generally reserved for specialized industrial applications.

So if you understanding specifics of each tool’s suitability for different concrete and masonry types, this will ensure that the chosen tool not only fits the job at hand but also performs optimally, extending the tool’s life and achieving the desired outcomes with efficiency and precision.

Choosing the Right Tool for Your Project

Selecting the optimal tool for concrete drilling or cutting hinges on a clear understanding of your project’s specific requirements. Here’s how to ensure you make the best choice:

Assess Project Needs

- Determine the Scope: Consider the size and scale of your project. Are you drilling a few holes for home improvement, or are you undertaking a large-scale construction project?

- Understand Material Characteristics: Identify the type of concrete or masonry you’ll be working with. Is it reinforced? How thick is it? These factors significantly influence tool selection.

- Precision Requirements: Define the level of accuracy needed. High-precision tasks may necessitate specialized equipment like diamond core drills, whereas standard masonry bits may suffice for more general applications.

Balancing Cost, Efficiency, and Precision

- Cost-Effectiveness: For smaller or one-off projects, consider cost-effective tools that offer reasonable precision and efficiency. Masonry drill bits and carbide-tipped hole cutters are good examples. Renting high-cost equipment for short-term use can also be economical.

- Efficiency vs. Precision: High-efficiency tools save time, especially on larger projects. However, precision should not be compromised. Tools like rotary hammer drills provide a good balance for most projects. Evaluate whether the speed of completion or the accuracy of the work is more critical for your project.

- Long-Term Value: For professionals or frequent DIYers, investing in high-quality, versatile tools like SDS drills can be more cost-effective over time. Consider the tool’s durability, maintenance needs, and versatility for future projects.

Tips for Selection

- Research and Reviews: Look into product reviews and recommendations within the construction community. User experiences can offer invaluable insights into a tool’s performance and reliability.

- Safety and Comfort: Consider ergonomic designs and safety features, especially for tools requiring physical exertion or posing higher risk levels. Comfortable and safe operation can enhance efficiency and precision.

- Expert Advice: When in doubt, consult with professionals. Hardware store experts, construction professionals, or online forums can provide tailored advice based on your project specifics.

By meticulously assessing your project’s needs and weighing the trade-offs between cost, efficiency, and precision, you can identify the tool that not only meets your immediate requirements but also offers the best value and outcomes in the long run.

Safety Considerations

When engaging in concrete drilling or cutting, prioritizing safety is paramount. The inherent risks associated with high-powered tools and the physical nature of concrete work demand vigilance and proper safety measures. Here’s a guide to ensuring a secure working environment:

Importance of Safety

Using concrete drilling tools involves significant risk, including exposure to silica dust, potential for flying debris, and the physical danger posed by high-powered, rotating equipment. Adhering to safety protocols not only protects you and those around you but also ensures the job is completed efficiently and effectively.

Essential Safety Gear

- Eye Protection: Wear safety goggles or face shields to protect against flying particles and dust.

- Hearing Protection: Concrete drilling can be exceedingly loud. Use earplugs or earmuffs to safeguard your hearing.

- Respiratory Protection: To prevent inhalation of harmful dust, especially silica from concrete, a proper respirator or dust mask is crucial.

- Protective Clothing: Durable work clothes, gloves, and sturdy boots can protect against cuts, abrasions, and impacts.

- Dust Suppression Systems: When available, use tools with integrated dust collection or suppression systems to minimize airborne particles.

Safe Practices

- Read the Manual: Before using any tool, familiarize yourself with its operation, safety features, and recommended use by reading the manufacturer’s manual.

- Check the Tool Before Use: Inspect the tool for damage or wear, particularly the bits or blades, to ensure they are in good condition and securely attached.

- Secure the Work Area: Ensure the work area is clean, well-lit, and adequately ventilated. Use barriers or signs to keep bystanders at a safe distance.

- Use the Right Technique: Apply steady pressure without forcing the tool, and maintain a stable stance to control the tool effectively.

- Emergency Plan: Have a first aid kit readily available and know how to quickly turn off the tool. Be aware of how to contact emergency services if necessary.

Adherence to these safety considerations is essential, not only for personal protection but also to maintain a high standard of workmanship. Regular training and staying updated on the latest safety protocols can further enhance safety in concrete drilling projects.

Maintenance and Care for Drilling Tools

Proper maintenance and care are crucial for maximizing the lifespan and performance of concrete drilling tools. Here are some tips to ensure your tools remain in top condition:

Regular Cleaning

- Remove Dust and Debris: After each use, clean your tools to remove concrete dust and debris, which can cause wear and tear over time.

- Lubricate Moving Parts: Apply appropriate lubricants to moving parts to reduce friction and prevent rust.

Inspect and Replace Wear Parts

- Check for Wear: Regularly inspect bits, blades, and other wear parts for signs of dullness or damage. Sharp and intact components not only work more efficiently but are also safer to use.

- Replace as Needed: Replace or sharpen bits and blades to maintain optimal performance. Using worn components can strain the tool and lead to premature failure.

Proper Storage

- Dry Environment: Store tools in a dry, clean environment to prevent rust and corrosion.

- Organize: Keep tools organized and in their cases, if available, to protect them from accidental damage.

Follow Manufacturer’s Guidelines

- Consult the Manual: Adhere to the manufacturer’s maintenance recommendations, including guidelines for cleaning, lubrication, and part replacement.

- Use Recommended Accessories: Use only accessories and parts recommended by the manufacturer to ensure compatibility and avoid damaging the tool.

Conclusion

Selecting the right tool for concrete drilling is a critical decision that significantly affects the quality, efficiency, and safety of your work. Throughout this guide, we’ve explored various tools, from specialized concrete hole saws to versatile rotary hammer drills, each suited to different aspects of concrete work. By understanding the specific needs of your project, including the type of concrete, the precision required, and the project’s scale, you can make an informed choice that balances cost, efficiency, and precision.

We’ve also highlighted the paramount importance of safety considerations and the role of proper maintenance in extending the life of your tools. Remember, the right tool not only facilitates the task at hand but also contributes to the overall success and safety of your project.

As you contemplate your next concrete drilling project, carefully consider the specific requirements and challenges it presents. Armed with the knowledge from this guide, you’re well-equipped to select the tool that will not only meet but exceed your expectations, ensuring a successful and safe completion of your work.