Selecting the ideal masonry saw blade is a critical decision in both construction and DIY projects. The right blade not only determines the quality of the cut but also significantly impacts the project’s overall success. Masonry tasks require precision, and using an appropriate saw blade ensures clean, accurate cuts through tough materials like concrete, brick, and stone.

Moreover, the efficiency of a project hinges on using saw blades designed for specific masonry tasks. This can save time and reduce the need for do-overs. Safety is another paramount concern; the correct blade minimizes risks of accidents and injuries by reducing blade-related failures and kickbacks during operation.

Therefore, understanding the importance of choosing the suitable masonry saw blade is the first step towards achieving optimal results in any masonry-related task, ensuring that every cut contributes towards the craftsmanship and integrity of the final structure.

Understanding Masonry Saw Blades

Masonry saw blades are specialized tools designed for cutting through a variety of hard materials. This include concrete, bricks, stones, and tiles. These blades are engineered to tackle the demanding nature of masonry work. They offer durability and efficiency that standard saw blades cannot match.

The key to their effectiveness lies in the materials used for their construction. They are typically comprised of high-strength abrasives or diamond segments.

Materials and Construction on Masonry Saw

Diamond Blades

These are the most popular and effective for cutting masonry materials. Diamond blades feature a steel core lined with diamond segments on the rim. It provides the hardness necessary to cut through stone and concrete. The diamonds, being the hardest materials on Earth, offer unmatched cutting capabilities.

Abrasive Blades

Made from a composite of abrasive materials, these blades are suitable for cutting through softer masonry materials. They wear down over time as the abrasive materials grind against the masonry.

Cutting Techniques

Wet Cutting vs. Dry Cutting

Masonry saw blades can be designed for wet or dry cutting. Wet cutting blades are used with water to cool the blade, reduce dust, and extend the blade’s life. Dry cutting blades are more suited for projects where water use is impractical or undesirable.

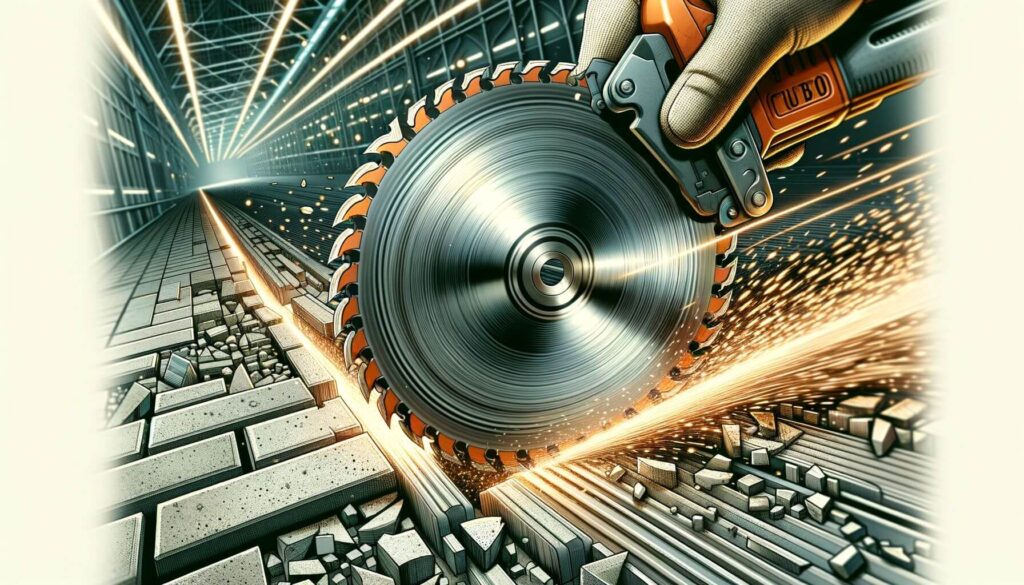

Masonry Saw Blade Design

The design of a masonry saw blade influences its cutting performance and suitability for various materials. For instance, some blades have a continuous rim to produce smooth cuts ideal for tiles and stone. Also others feature segmented rims with gaps to prevent overheating, suitable for cutting through concrete.

The choice of blade influences not just the quality of the finished work. It is also the efficiency with which the project is completed. Therefore, it’s crucial to match the blade to the specific requirements of the material being cut to ensure optimal performance and longevity of the blade.

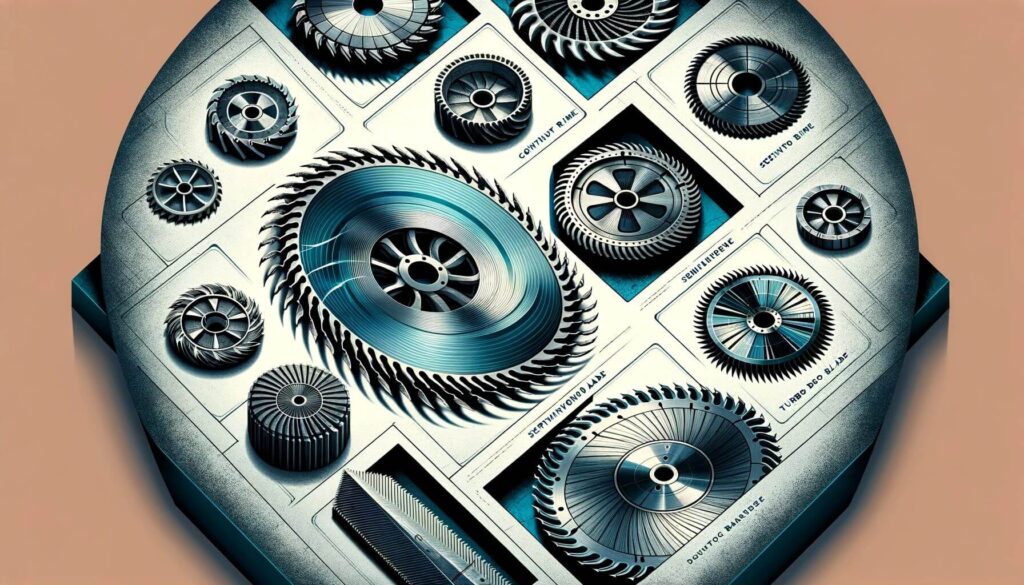

Types of Masonry Saw Blades

When selecting a masonry saw blade, understanding the different types available is crucial to finding the perfect match for your project. Each type is designed with specific features to optimize performance for various masonry materials and applications.

Continuous Rim Blades

Continuous rim blades are designed to deliver chip-free cuts, making them ideal for materials that are prone to cracking and chipping, such as ceramic tile, marble, and granite. Also, the continuous rim allows for a smoother cut, but these blades operate best at slower speeds and may require water to keep the blade cool during the cutting process.

Segmented Blades

Segmented blades are easily identifiable by the gaps or segments along the rim that help dissipate heat quickly, allowing for faster cutting speeds. These are suitable for cutting through harder materials like concrete and brick. The segments also help remove debris from the cut, reducing wear on the blade. However, they may not produce as smooth a cut as continuous rim blades.

Turbo Blades

Turbo blades combine the best features of segmented and continuous rim blades, featuring a continuous rim enhanced with segments or notches. This design allows for faster cutting like segmented blades while maintaining a smoother finish similar to that of continuous rim blades. Turbo blades are versatile, suitable for a range of materials from concrete to tile, making them a popular choice for both DIY and professional projects.

Abrasive Blades

Unlike diamond-tipped blades, abrasive blades wear away as they cut, made from materials like silicon carbide or aluminum oxide. They are cost-effective for projects requiring the cutting of softer masonry materials but have a shorter lifespan and tend to produce more dust.

By understanding the characteristics and best uses of each type of masonry saw blade, you can make an informed decision that ensures efficiency, quality, and safety in your masonry projects. Therefore, matching the blade to the specific requirements of your job is key to achieving optimal results.

Choosing the Right Blade

Selecting the right masonry saw blade for your project involves more than just matching the blade to the material. Several factors should be considered to ensure you choose a blade that not only cuts effectively but also maximizes efficiency and safety. Here’s how to make an informed choice:

1. Assess the Material

First, identify the specific type of material you will be cutting. Different materials require different blade specifications. For example, dense materials like granite or porcelain will need a diamond blade with a soft bond to ensure efficient cutting, while softer materials like limestone are better matched with a blade that has a harder bond.

2. Wet or Dry Cutting

Decide whether you will be performing wet or dry cutting. Wet cutting blades are designed to be used with water to reduce dust and cool the blade, extending its lifespan. Dry cutting blades are more versatile and can be used without water, making them suitable for situations where water use is impractical.

3. Blade Size and Compatibility

Ensure the blade size is compatible with your saw. Using a blade that is too large or too small for your saw can be unsafe and may reduce the efficiency of your cuts. Also, consider the arbor size to ensure a proper fit.

4. Cutting Speed and Finish

Consider how fast you need to complete your project and the finish quality you require. Turbo blades and segmented blades are ideal for fast cutting, while continuous rim blades offer a smoother finish for materials that are prone to chipping.

5. Budget and Blade Lifespan

Evaluate your budget and the expected lifespan of the blade. While high-quality diamond blades may have a higher upfront cost, their durability and efficiency can provide better value over time compared to cheaper, abrasive blades that wear down more quickly.

6. Safety Features

Look for blades that come with integrated safety features, such as anti-vibration technology and cooling holes, to enhance the user’s safety and comfort during operation.

7. Read Reviews and Recommendations

Researching product reviews and seeking recommendations from industry professionals can provide additional insights into the performance and reliability of different masonry saw blades. Therefore, choosing the right blade involves balancing these factors to find a blade that meets the demands of your project while ensuring safety and efficiency.

You should take the time to carefully select a masonry saw blade can significantly impact the success of your project, resulting in cleaner cuts, faster completion times, and a safer work environment. Remember, the best blade for masonry is one that fits the specific needs of your job and your equipment.

Maintenance and Safety Tips

Proper maintenance and adherence to safety protocols are paramount when using masonry saw blades. Ensuring your blades are well-maintained not only extends their lifespan but also enhances performance and safety during cutting operations. Here are essential maintenance and safety tips to follow:

Maintenance Tips

Regular Inspection

Before and after each use, inspect the blade for signs of wear, damage, or missing segments. A damaged blade can be hazardous and less efficient.

Cleaning

Keep the blade clean from debris and dust. Build-up can affect cutting performance. For wet cutting blades, ensure they are dried properly after use to prevent rust.

Proper Storage

Store blades in a dry, secure place to prevent damage. Hanging them individually or keeping them in their original packaging is advisable to avoid accidental contact with hard surfaces.

Sharpening

Diamond blades can be sharpened by cutting into an abrasive material, such as a block of soft concrete or a special dressing stone, to reveal new diamond edges.

Usage

Using the blade for its intended material and cutting type (wet or dry) prevents premature wear and ensures optimal performance.

Safety Tips

Personal Protective Equipment (PPE)

Always wear appropriate PPE, including safety goggles, gloves, ear protection, and a dust mask when cutting dry.

Correct Installation

Ensure the blade is correctly installed and securely fastened before use. The blade’s direction should match the saw’s rotation.

Water Use for Wet Cutting

When using wet cutting blades, maintain adequate water flow to the blade to prevent overheating and reduce dust.

Avoid Forcing the Blade

Let the blade do the work. Forcing the blade into the material can cause overheating, blade damage, or even breakage.

Check for Overheating

If a blade becomes too hot, it can warp and become damaged. Pause cutting and allow the blade to cool if you notice discoloration or reduced performance.

Work Area Safety

Ensure the work area is secure and that you have a firm footing. Keep bystanders at a safe distance, especially when cutting materials that may produce hazardous dust.

Saw Maintenance

Regularly check your saw’s condition, including the arbor, flanges, and any safety guards. A well-maintained saw contributes to safer operation.

If you follow these maintenance and safety tips, you can ensure that your masonry saw blade remains in top condition, providing you with reliable performance while minimizing the risk of accidents. Remember, taking care of your tools is as crucial as the skills you apply in using them.

Innovative Features in Modern Masonry Blades

The evolution of masonry saw blades has been marked by significant technological advancements, leading to improved performance, longer lifespan, and enhanced user safety. Manufacturers are continually innovating to meet the demands of modern construction and DIY projects. Here are some of the innovative features found in today’s masonry saw blades:

Advanced Diamond Matrix

Modern blades are equipped with an advanced diamond matrix that allows for more efficient cutting and longer blade life. This technology ensures that as the blade wears down, new diamond edges are exposed, maintaining the blade’s cutting ability.

Cooling Features

Many contemporary masonry saw blades incorporate cooling features, such as specially designed segments or gullets that help dissipate heat more effectively. This not only prevents the blade from overheating but also reduces the risk of warping and extends the blade’s lifespan.

Noise-Reduction Design

Noise can be a significant concern in construction environments. Some modern blades now feature noise-reduction designs, using specially engineered segments or silent cores that minimize sound levels during operation, contributing to a more comfortable working environment.

Anti-Vibration Technology

Vibration can lead to user fatigue and imprecise cuts. To combat this, some blades are designed with anti-vibration technology, which reduces vibration and enhances user comfort and control during cutting.

Improved Safety Features

Safety remains a top priority, and modern masonry blades often come with enhanced safety features. This includes reinforced cores and segments for added durability and reduced risk of breakage, as well as laser-cut expansion slots that help prevent blade warping under extreme heat.

Eco-Friendly Options

With a growing emphasis on sustainability, some manufacturers are now producing eco-friendly masonry saw blades. These blades are made with recycled materials and designed to produce less waste, aligning with green building practices.

Versatility

The latest masonry saw blades are designed to be more versatile. They are capable of cutting through a wider range of materials with precision and efficiency. This versatility reduces the need for multiple blades and simplifies the cutting process.

Customizable Blade Options

Beyond standard innovations, some manufacturers are now offering customizable blade options, allowing users to select specific features tailored to their project’s needs. This could include variations in segment height, bond hardness, or even the type of diamond used, providing a personalized tool that perfectly matches the user’s requirements.

Wear Indicators

Another helpful feature being added to some masonry saw blades is wear indicators. These indicators provide a visual cue to the user, signaling when a blade is nearing the end of its useful life and needs replacing. This feature helps prevent the potential for blade failure and ensures that users are always working with tools that are in optimal condition.

Improved Segment Bonding

The durability of a blade is significantly influenced by how well the cutting segments are bonded to the blade core. Recent innovations have introduced improved bonding techniques that ensure segments remain attached longer under harsh cutting conditions. This not only extends the life of the blade but also maintains its cutting efficiency, reducing the need for frequent replacements.

Multi-Purpose Blades

Recognizing the diverse needs of users, the latest blades are being designed for multi-purpose use, capable of cutting through various materials without sacrificing performance. This versatility allows for a single blade to be used in different applications, from cutting concrete and bricks to slicing through metal reinforcements, making them highly valuable for projects with mixed material requirements.

These innovative features represent the cutting edge of masonry saw blade technology, reflecting the industry’s commitment to improving performance, safety, and environmental responsibility. By staying informed about these advancements, professionals and DIY enthusiasts can make more informed choices, ensuring they select the best blade for their specific needs and benefit from the latest developments in masonry cutting technology.

Last Words Masonry Saw Blades

The landscape of masonry work is ever-evolving, driven by advancements in tooling and technology that aim to meet the growing demands of both professionals and DIY enthusiasts. The development of masonry saw blades is a prime example of this evolution, showcasing a remarkable journey from simple cutting tools to sophisticated instruments equipped with a variety of innovative features designed to maximize efficiency, precision, and safety.

Today’s masonry saw blades are a testament to the industry’s dedication to innovation, offering features such as advanced diamond matrices, cooling and noise-reduction technologies, anti-vibration mechanisms, and eco-friendly designs. Also, these advancements not only enhance the cutting experience but also contribute to safer, more sustainable work practices.

Last, the introduction of customizable options and wear indicators further exemplifies the user-centric approach manufacturers are taking, ensuring that every cutting task, regardless of its complexity or the material involved, can be completed with optimal results.

As we look towards the future, the continuous refinement of masonry saw blade technology promises even greater possibilities for efficiency and performance. For professionals and DIY enthusiasts alike, staying informed about these developments is key to selecting the right tools for their projects, ensuring not only the success of their work but also their safety and satisfaction.

In sum, the right masonry saw blade can make a significant difference in the outcome of a project. By choosing a blade that aligns with the specific needs of the task at hand, users can enjoy a smoother, faster, and more enjoyable cutting experience. Thus, the ongoing innovations in blade technology serve as a reminder of the potential to achieve even greater heights in masonry work, pushing the boundaries of what is possible in construction and renovation projects.